As a systems manufacturer and integrator, Pneumotech has the ability to supply almost any requested brand name including our own private label systems. Spanning the full gamut- from 1/10 hp to 1500 hp with flows to 3200 SCFM and pressures to 9000 PSIG – we offer everything from individual components to complete turnkey systems.

As a systems manufacturer and integrator, Pneumotech has the ability to supply almost any requested brand name including our own private label systems. Spanning the full gamut- from 1/10 hp to 1500 hp with flows to 3200 SCFM and pressures to 9000 PSIG – we offer everything from individual components to complete turnkey systems.

Instrument Air Systems

Instrument quality compressed air is not only usable for instrumentation, but also very well suited for general compressed air throughout most facilities. Instrument quality compressed air should have a pressure dewpoint 20°F below the lowest recorded ambient temperature across the system. The compressed air stream should also have negligible particulate contamination and oil vapor carry through, down to a filtration level typically around .01 microns or less.

Vacuum Pumps

It is a pressure that is below the normal atmospheric pressure which you reside in. That being said, you’ll find that the ability to achieve this “lower than atmospheric pressure” can sometimes be extremely difficult. Without the proper equipment for the depth of vacuum you’re trying to achieve, and without the vacuum pump that will withstand the inhalants it’s pulling in during its evacuation, you will find yourself spending a tremendous amount of money and time getting nowhere.

It is a pressure that is below the normal atmospheric pressure which you reside in. That being said, you’ll find that the ability to achieve this “lower than atmospheric pressure” can sometimes be extremely difficult. Without the proper equipment for the depth of vacuum you’re trying to achieve, and without the vacuum pump that will withstand the inhalants it’s pulling in during its evacuation, you will find yourself spending a tremendous amount of money and time getting nowhere.

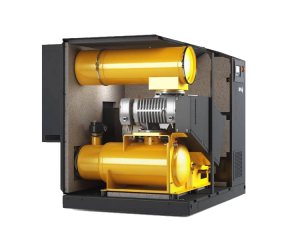

Compressors

Air compressors come in two basic configurations; positive displacement (reciprocating or rotary screw), and dynamic (centrifugals or regenerative). Of these two basic configurations, there exists many variations in their design, and each design will have it’s own advantages and disadvantages when considered in a particular application.

Lubrication

Prior to providing automatic and manual lubrication systems and services, Pneumotech discovered through the years that our customers were often purchasing unneeded lubricants based on salesmanship and pricing but not based on actual requirements or needs. While most lubrication problems are caused by equipment oils not being changed often enough, waste happens when they are changed too often.

Main Line Equipment

Mainline equipment is an all inclusive statement, concerning everything required on the main compressed air line, from the compressed air piping and full flow regulator’s to dryers and filters. Proper compressed air treatment is essential to the continual operation and life of the equipment that utilizes the compressed air.

After-coolers, refrigerated dryers, desiccant dryers, line filters, centrifugal separators.

Blowers

Blowers come in at least as many variations as automobiles. They are used mainly for high-volume, low-pressure applications – however they can also be used for high-volume vacuum applications. There are many variations available in the blower theme.

Whether you need a rotary lobe blower, a regenerative blower or a consultation on what will suit you best, we would be more than happy to review your equipment requirements and assist you making a qualified decision for your applications requirements.

We offer a full range of blowers to fit your needs.

Compressed Gas Generators

Gas generation, is really kind of a misnomer; technically what is commonly offered in the low pressure applications is gas separation. The process is much more akin to filtration.

Components

The list of components available on the market today is extensive. Pneumotech has built relationships with the leading manufactures to ensure you have access to the most complete lines of componentry including the best known brands. Our staff is well trained and has many years of experience in design, building, repairing and replacing the components in your workplace.

Whether you need valves, cylinders, lubricants, parts or pumps; we have the ability to supply what you need without wasting your resources on things that you don’t.